Careers at Alpine Aviation Group

Alpine Aviation Group seeks highly qualified personnel to join us in our growth and success. We value integrity, trust, diversity, and ingenuity. We strive to provide a high quality, drug-free, team-oriented environment and offer our employees great benefits!

What we offer:

- Competitive Compensation

- Paid Leave (Three weeks of PTO vacation/sick time)

- Employer-paid Medical, Prescription, Dental and Vision Plans

- Employer funded HRA ($2K single/$4K family)

- Employer-paid Life Insurance ($100K per employee)

- Employer-paid Short and Long-Term Disability Plans

- Paid Holidays (11 per year)

- Simple IRA Plan (contributions matched up to 3% of salary)

To apply for a position, please send your resume to [email protected].

Current Open Positions

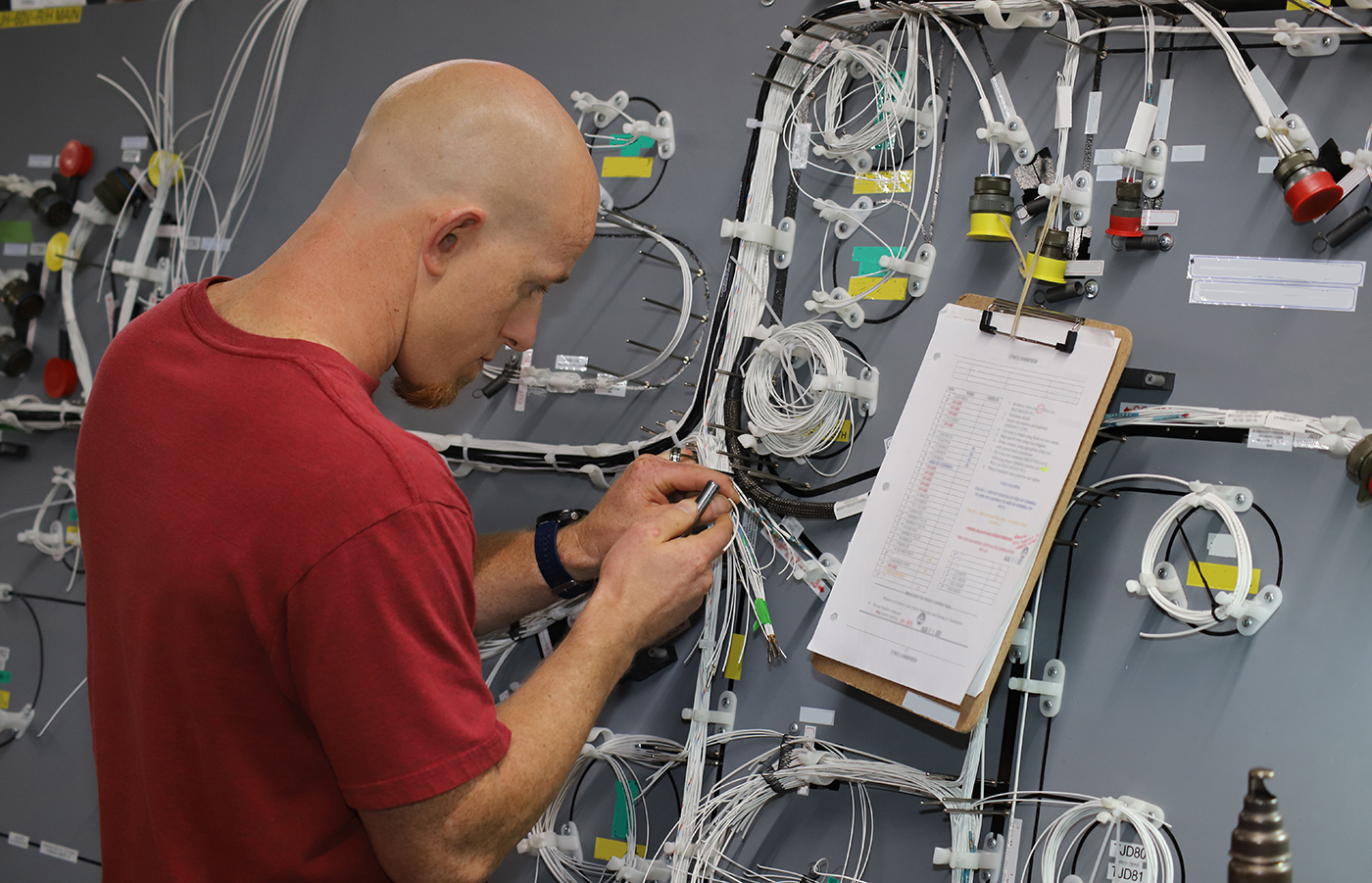

FABRICATOR (FULL-TIME)

Primary Responsibilities:

- Fabricate wire harnesses and cables by cutting, sorting/inventory, color-coding, measuring, stripping, crimping, soldering, and routing various lengths, types, and gauges of wire, heat-shrink, and other related materials.

- Operate tools and equipment such as wire strippers, crimpers, solder iron, wire identification and cutting machines, heat guns, and other associated tools.

- Inspect and test wiring installations, assemblies, or circuits for resistance factors.

- Complete job process tracking associated with work assignment.

- Ensure all assemblies and detail parts are free of FOD and non-conformance issues.

- Inspect and ensure that materials, components, sub-assemblies, assemblies, tools, and product configurations conform with engineering drawings, company quality policies, and applicable industry standards.

- Work with co-workers and management in problem solving, exploring, and implementing best practices in our operation.

Primary Qualifications:

- Mathematical aptitude to perform shop math and basic understanding of drawings/schematics.

- High School Diploma or equivalent and 2 years of relevant work experience.

MANUFACTURING SALES REPRESENTATIVE (FULL-TIME)

Alpine Aviation Group seeks a full-time Manufacturing Sales Representative/Business Developer with strong sales experience in aviation platform wiring systems for fabrication & aviation certification processes. The candidate must be willing to travel to potential customer facilities, and attend government and industry conferences & symposia. Salary & commission are commensurate with experience. Alpine Aviation Group is amenable to either an independent contractor or employee relationship.

Responsibilities:

- Drive sales process from opportunity development, pursuit, and closure.

- Develop and implement strategic plans for long-term sustained sales growth.

- Establish and grow business relationships with both government and commercial customers.

- Conceive, collaborate, and execute strategies to grow Alpine’s revenue.

- Initiate site visits, telephone sales, video conferencing, trade show participation, etc. to develop new business relationships.

- Meet sales goals and commitments to sustain Alpine Aviation’s continued growth.

- Work with team on proposal pricing and contracts.

Qualifications:

- Proven ability to interact with the target customers at all levels with demonstrated experience in closing sales transactions for both domestic and international customers.

- Ability and willingness to travel to all account activities.

- Track record of success of meeting or exceeding sales goals while building long term customer relationships.

- Experience with direct customer interaction in support of US Government programs, particularly with DOD aviation programs.

- Familiarity with the US Army aviation programs is a plus.

- Excellent written and verbal communication skills including the ability to present technical and product solutions to all audiences.

- The ability to engage and communicate with cross-functional teams comprised of Engineering, Production, and Management.

- Experience in Government contract vehicles supporting procurement activities.

- Five + years of work experience in marketing of DOD programs.

US Citizenship required.

Alpine Aviation Group is an Equal Opportunity Employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, or status as a protected veteran.